Recycling, eco-design and Industry 4.0 technologies to recover high-value metals in the electric vehicle chain

RELOAD, circular economy in the CEV

The overall objective of the RELOAD project is to contribute, in an efficient and safe way, to the supply of high-value metals in the industrial value chain of the Connected Electric Vehicle (CEV). In this way, it will be possible to reduce dependence on imports and promote a sustainable, circular industrial model with a smaller environmental footprint.

Period: July 2022 - June 2025

Total project budget: 7,284,256.10€

Balidea budget: 512,864.10€

It is part of the Future: Fast Forward (F3) tractor project, within the framework of PERTE-VEC

Support received

This project has been funded by the Ministry of Industry, Trade and Tourism through the Recovery, Transformation and Resilience Plan, thanks to the NextGenerationEU programme, the COVID-19 economic recovery package for EU Member States.

Project

Specific objective

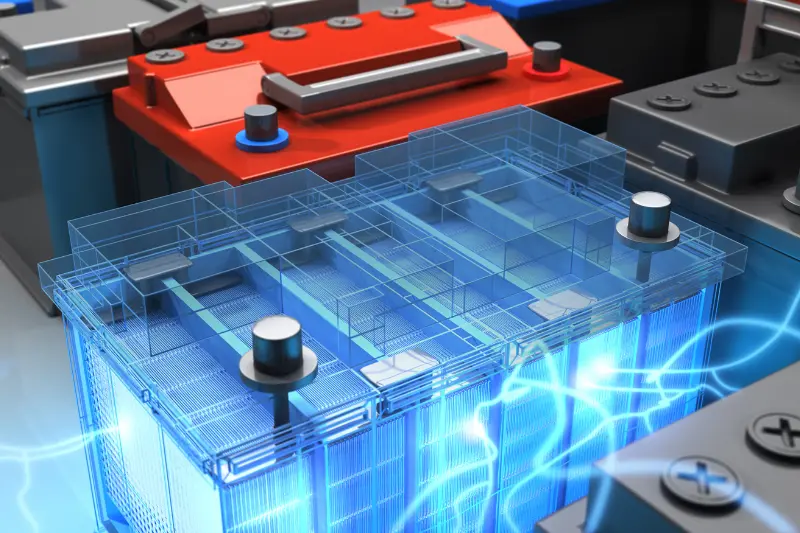

Research into different recycling, eco-design and Industry 4.0 technologies to recover high-value metals present in electronic components, lithium-ion batteries and electric motors at the end of the CEV's useful life. In this way, they can be re-incorporated into the value chain, establishing a circular model.

Consortium

Partners and collaborators

RELOAD is part of the tractor Future: Fast Forward (F3) project, within the framework of the PERTE Connected Electric Vehicle (CEV). It is led by the company ENSO. The consortium, together with Balidea, also includes the companies SEAT, S.A., Técnicas Reunidas and Asai Industrial, and the research organisations Multisectoral Research Technological Centre (CETIM), the University of Zaragoza and the National Metallurgical Research Centre (CENIM) of the Spanish National Research Council (CSIC).

Future: Fast Forward

Balidea's role

Guaranteeing the traceability of metals

Balidea participates in RELOAD by integrating digital technologies as facilitating tools for the promotion of recycling processes. Recycling technologies that guarantee the traceability of metals are being investigated, thus promoting the circular economy.

Blockchain-based digital prototype

It will design a digital prototype based on BlockChain technology, which guarantees the traceability of metals throughout the value chain: from the manufacture and use of these components to the recovery and reuse of metals to ensure their sustainability and the efficient use of resources.

AI-based predictive model

Balidea will carry out research for the creation of a functional and predictive model based on Artificial Intelligence (AI) to predict the availability and demand of recovered products/metals of interest to the Spanish automotive sector and, therefore, help to plan their optimal use.

The digitisation of the metal recovery process within the electric vehicle manufacturing chain also involves data analysis, localisation and digital certification.

Definition of KPIs

Definition of new circularity metrics and indicators, based on a thorough review of European and Spanish regulations on electronic components and batteries.

Digital map of metals

Research to design a dynamic digital model or map of the circulation of metals, in order to facilitate their use, recovery and reuse in three use cases: batteries, electric motors and electronic components.

Digital battery passport

In collaboration with SEAT, we will design an European digital passport for electric vehicle batteries.